The Institute for Energy Efficiency in Production EEP at the University of Stuttgart has been surveying current and planned energy efficiency activities in German industry every six months since 2013. The EEI is compiled in cooperation with the German Energy Agency (dena), the Federation of German Industries (BDI), Fraunhofer IPA and TÜV Rheinland, as well as further partners.

In the current survey period from 4 April to 17 May 2022, a total of 913 participants commented on the three sub-indices and in particular on the topics of crisis, decarbonisation and the need for support in their own companies.

The investment index has now stabilised at a much lower level after a sharp drop during the pandemic. The productivity index continues to rise, meaning that companies have increasingly ambitious efficiency targets. Being efficient has long become a pure necessity. However, there is a wide gap between the expectation and the actual situation of energy efficiency in companies.

Reaction to the war

The majority of companies expect a further increase in the importance of energy efficiency in the coming 12 months. This is hardly surprising in view of the uncertain energy situation in the coming winter, caused in particular by the Ukraine war, and the already rapidly rising energy prices, but it is nevertheless striking.

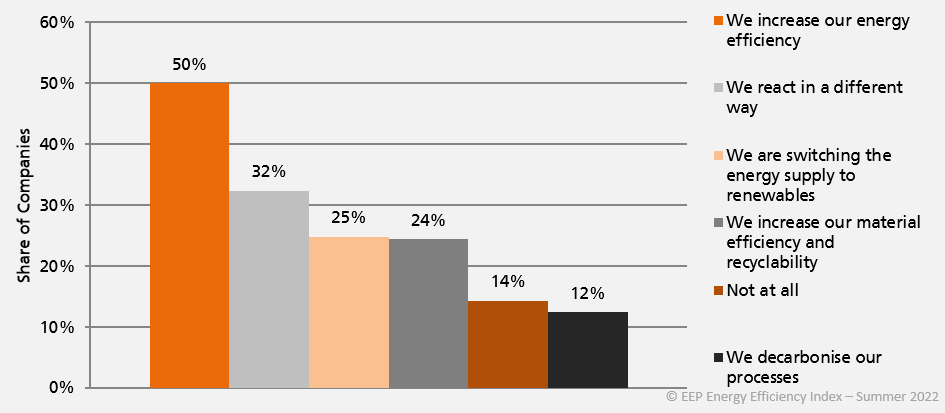

Compared to the survey a year ago, more than twice as many companies, and thus the absolute majority, rate the importance of energy efficiency as relatively high. Consequently, more than half of the companies are reacting to the current crisis, as well as price and supply uncertainty with efficiency-enhancing measures. However, energy-intensive companies are the most hesitant to react.

Figure 1: How is your company reacting to the current crisis and the resulting price increases & supply shortages? (Multiple choice, n = 865, n'= 1371) ©EEP University of Stuttgart - Download

What approaches are companies using to increase efficiency and resilience?

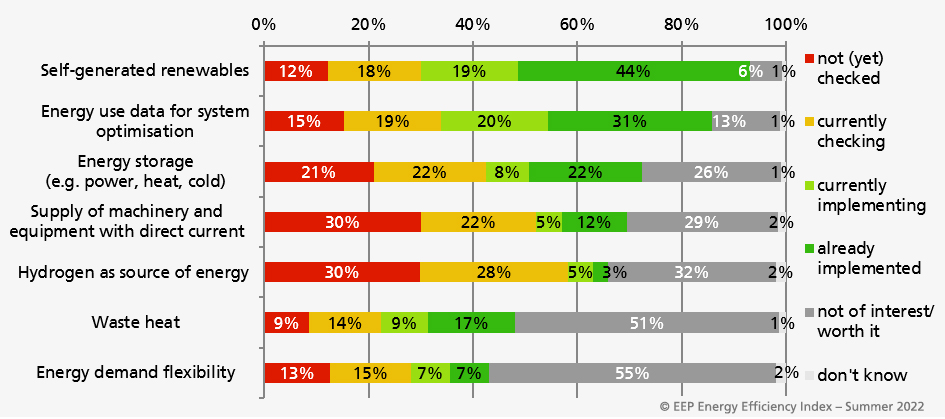

There is, overall, a high willingness to transform towards self-generated renewables, system optimisation and energy storage. The use of direct current and hydrogen are considered interesting but rarely explored.

The majority of participating companies rates the use of waste heat and the flexibilisation of one’s own energy demand as not of interest. This is surprising because there is a high scientific-economic consensus for the potential of these instruments. However, they are apparently not being tapped by industry. This is tragic because these two measures can be particularly helpful in saving gas in a situation of gas shortage: More than 60% of industrial energy demand is used for (process) heating and cooling and largely depends upon gas. The explanation for this could be a lack of information on potentials, procedures or a lack of appropriately qualified personnel.

Figure 2: Where does your company currently stand with regard to the use of... (851 ≤ n ≤ 858) ©EEP University of Stuttgart - Download

There is a need for information and support especially for hydrogen and direct current

According to their own statements, companies have a great need for advice. Particularly in the case of hydrogen and direct current supply, there is a high demand both for more information and for advice and implementation support. With the innovation network "Climate Neutral Companies", the EEP in cooperation with Fraunhofer has created a platform to support manufacturing companies in this.

"The manufacturing industry in Germany is ready to do its part for a climate-neutral economy. However, it needs politicians to set the course for this," summarises EEP Director Professor Alexander Sauer. "The internationally uncertain energy supply due to the Ukraine conflict is unavoidable in the short term. Both renewable energies and energy efficiency are the levers to reduce dependencies and successively ensure a sustainable supply."

Contact

Dipl.-Volkswirt Stefan M. Buettner

Project Manager Energy Efficiency Index of German Industry

EEP – University of Stuttgart

Nobelstr. 12, D-70569 Stuttgart, Germany

Tel: +49 (711) 970-1156

stefan.buettner@eep.uni-stuttgart.de