Even though 125 years ago Nikola Tesla won the electricity battle with AC technology against Thomas Edison, who favoured DC, DC technology will be a key element of energy transmission in the process of the energy transition. Innovations in semiconductor technology make this change possible and lead to the circumstance that we already live in a world of direct current, if unnoticeably so. DC grids are used, for example, for the transmission of energy in the high-voltage range, the integration of photovoltaic systems and batteries, in computer centres and in on-board networks for aircraft as well as ships and cars.

The large potential of the DC power supply in production lies in coupling the factory's electrical systems to form a DC smart grid. The DC Smart Grid enables simple stabilization of the electrical supply and can thus increase production availability. A fast adaptation of the energy system to the optimal operating point allows for the development of energy savings and flexibility capacities.

The transfer of the DC Smart Grid approach from the pilot plant to industrial production comes with technical and economic challenges. We offer our customers individual system solutions that are catered to their specific needs and lead to the highest possible cost reduction and refinement of resource efficiency.

Competencies and Services

- Detection and analysis of the DC potential

- Design, project planning and commissioning of DC networks

- Design and integration of energy generators and storage facilities to increase energy efficiency, flexibility, as well as quality and security of supply

- Training of personnel and equipment evaluation

- Development and implementation of a DC Smart Grid for the control and regulation of energy flow in a DC network

Your contact: Sebastian Weckmann

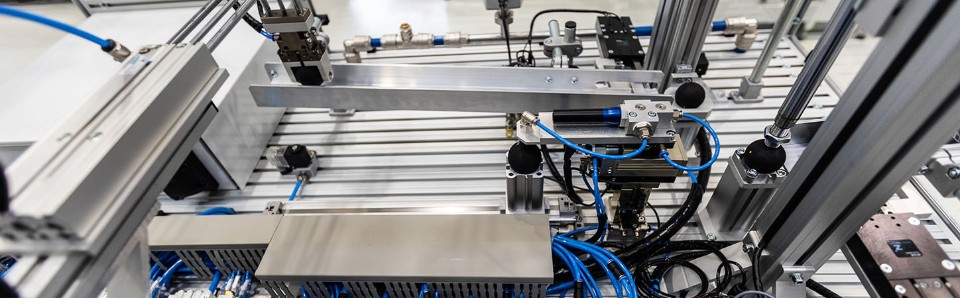

Compressed air systems are a widespread cross-sectional technology in manufacturing companies. The generation of compressed air, however, comes coupled with high energy consumption and is therefore an expensive form of energy. In the course of digitalisation in industry, specific measures can be taken to make use of existing efficiency capacities and significantly cut down on costs.

Air is not intelligent. Our systems are. We’ll show you how.

An important research focus in the field of intelligent compressed air systems for EEP is the integration of Smart Services. The transfer of Smart Grid and Industry 4.0 solutions to compressed air systems allows for a more efficient design by means of platform-based services. Modern software methods result in comprehensive advantages in the form of efficiency measures that can even be applied to older systems, holistic system considerations from the valve to the business model and early detection of anomalies before system failures.

Competencies and Services

Focused on the development of practice-oriented solutions, the EEP works on the optimisation of compressed air use and innovative future strategies for companies. For this purpose, individual capacities and constraining factors are determined:

- Keeping an eye on the market: Selection of customized I4.0 solutions

- Industry meets Laboratory: Evaluate products for use in industry in our industry-related test environments

- Gain added value from data: Increasing efficiency with machine learning methods

- From strategy to solution: development of company-specific strategies for compressed air use

Your contact: Martin Reisinger